By now everyone is completely familiar with the ubiquitous term “Green” for environmental concerns. Being a responsible steward of the environment is not only good for your overall karma, as it’s the right thing to do; it’s also proven to be great for business.

As we’re in the graphic communications industry, I’m sure you are aware of the color wheel. The opposite of green on the color wheel is red. So environmentally speaking, if you aren’t a “Green Printer” does that make you a “Red Printer” if you don’t develop a sustainability program? Think about it. What are you doing in your shop today, that’s environmentally friendly?

Just recycling your soda cans doesn’t count. Is that the best you can do?

Have you ever looked at what it would take to get something going and really do it right? The adage “A journey of a thousand miles begins with one step” is really true. I am extremely proud of the fact that Visual Impressions, where I’m the COO, just became the next printer in the United States to become Sustainable Green Printing Partnership (SGP) certified (https://www.sgppartnership.org/). Our journey took a little over a year, and with a lot of hard work, creative thinking, teamwork, research, and support we accomplished our goal.

Well, so what you ask? What did you really accomplish you may wonder? Quite a lot actually.

First we established a Sustainability Committee. This is a group of interested staff members that are tasked to develop our program and give their mental effort to drive our actions. We wrote a Sustainability Mission Statement that we use to guide our business, and for 2012 we voted to work to reduce our energy expenditure by 20%.

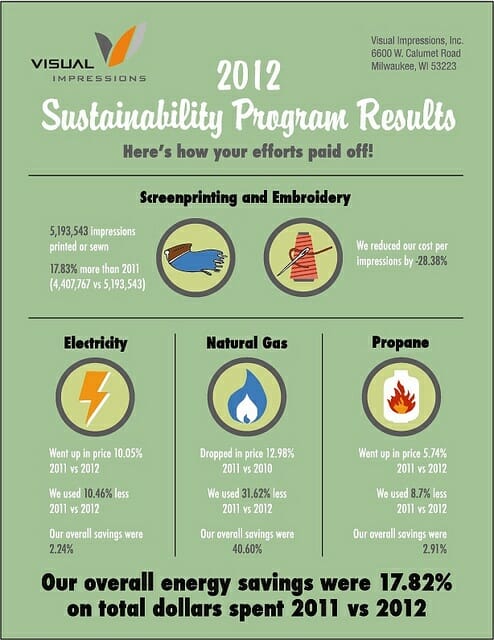

The committee developed SMART goals that focused our efforts, and laid the roadmap out for success. We worked all year on this effort and employed many tasks, such as installing motion sensors for lights in common areas like break rooms and bathrooms; lowering our dryer temperatures to correct levels, adjusting the thermostats in the shop and office, fixed equipment to perform better, keeping equipment turned off when not in use and other ideas. Small, easy and seemingly inconsequential things add up to big savings. Did we reach our goal at the end of the year? Actually no, but we did save 17.82% from our energy costs compared to 2011. As we’re in a 100,000 square foot facility and operate on two shifts, this was a good chunk of money. If you think about it in terms of your energy cost per imprint – we reduced it by 28.38%.

I also appointed a Sustainability Coordinator, Jake Gallas. Jake is one of our key managers already, and he is a great asset for this initiative. Most of the leg work moves through him, and he delegates the effort out to his staff. He also is responsible for coordinating all the training and daily follow up with our crew.

We signed up for an Energy Audit from our local utility and they provided us with a detailed report on our energy consumption. They also professionally validated a lot of our efforts and offered some tips to keep them moving forward.

Jake and I participated in several months of SGP support Peer to Peer webinars run by Marci Kinter from SGIA. These were wonderful, hour long talks that walked us through all the different facets on building our program and preparing us for our third party audit that earns you the certification. This was invaluable.

Through the SGP program we calculated our carbon footprint, measured our VOC’s and HAP’s, wrote policies and procedures on crucial aspects of the company (some were new; some were just formalizing existing ones). We also designed a training program for sustainability, safety and hazard communication for all employees. Because of the program, we also had some great conversations with our existing vendors and suppliers, and changed a few ways we order materials.

Our sustainability efforts weren’t just limited to our main goal of energy reduction either. We also had worked on several challenges such as eliminating the use of masking tape in the screen room, reusing cardboard boxes in a better way, recycling our ink into a new color, finding a recycler to help handle our materials, sourced a new shrink wrap for pallet wrapping, and other projects all aimed at the three “R”s – Reduce, Reuse or Recycle.

We also are participating in two local Milwaukee Sustainability Programs – ME2 & ME3. We started with the ME3 program (http://city.milwaukee.gov/ME3 – if you watch the documentary video we are featured) and obtained a grant that allowed us to bring in a team of engineers to audit Visual Impressions to help find ways to reduce our energy. They gave us a short list of potential projects, and we chose to examine the efficiency of our natural gas operated dryers for screen-printing. We are also using the grant money to convert our office lighting to LED’s.

The ME2 program (http://www.smartenergypays.com/) is also grant based, and its focus is helping companies with support for major capital investments, and we are using the money to acquire a new Kornit Avalanche direct to garment printer. The sustainability savings here is focused on driving more orders to be digitally printed, rather than traditionally screen-printed – which requires more effort, energy and process.

Our 2013 SMART goal that our Sustainability Committee developed is to reduce our landfill by 50% by the end of the year. We’ve finally teamed up with couple of recycling companies, and have put in place a program to segregate and recycle our waste cardboard, paper, plastic, metal, batteries, electronics, light bulbs, and waste chemicals. One final material that we’re having trouble with is finding someone that can use our scrap embroidery pellon stabilizer. At the time of this post, I have six companies working on it. (If anyone is recycling this material, please contact me!!)

All in all, we have made tremendous progress from doing virtually nothing at the end of 2011. (Then we just compacted and recycled our cardboard and soda cans) Since then our sustainability program has provided a value of well over $140,000 (savings and grant money combined). Not bad for a first year initiative.

So, if you are a “Red” printer and feel that this sustainability stuff is just a feel good, tree hugging exercise with little real value, think again. What are you waiting for? Take your first step and start with some low hanging fruit. Here’s what I would do:

- Contact SGP and learn how this program can help you. https://www.sgppartnership.org/

- Start a sustainability committee. Discuss what you can do with at your company. Set some simple goals.

- Get an Energy Audit from your local utility. It’s probably free. They will come out and poke around your building and should give you a report on what you can do to save energy. Follow their recommendations.

- Turn stuff off when not in use.

- Talk to your vendors, suppliers and customers – what can they do to help?

- Does your local area or government have any sustainability programs? Contact your chamber of commerce, city or county government, or just simply Google some key words. There is grant money available for switching out our lights, improving your building, even buying new equipment.

Hope this article helps you, and maybe even inspires you to do something different. I authored an article in Impressions Magazine in 2012 that may help you too – http://impressions.issshows.com/shirt-printing-business/Why-a-Sustainability-2110.shtml

Remember, you can’t do it all at once – just getting started is the key. You also, can’t do it alone; it’s a group effort.

I have many pictures of different sustainability ideas on my Pinterest board “Behind the Curtain at a T-shirt Shop” – http://pinterest.com/atkinsontshirt/behind-the-curtain-at-a-t-shirt-shop/

If you need help, please let me know and I’ll be happy to discuss how to get things going. matkinson4804@gmail.com.