Pardon the alliteration, I couldn’t help myself. Does the constant craving for samples from your customers drive you a bit nutty? If not tempered, it can quickly launch out of control.

Have you been pulling your hair out lately?

Samples for the most part are for someone else’s final decision making usually, but they can be for other purposes too, such as a photo shoot or a quality control procedure.

The intent for the article is to be more or less a walk through the sampling process to help you define your strategy on what might work for you in your shop. Just read and use what you like and change or discard the rest.

Ok, let’s get started…

Define Sample

That’s really the first step. There should be two types of production orders that you enter into your system. One is a sample order, the next is a “real” order. They could be for the same job. More on that later…

For our purposes, let’s say a sample is the “definitive proof of what the production outcome is going to be on the actual shirt used for the main production order”. Sometimes a digital mock up just won’t cut it.

One question first.

Producing a strike off is important to make sure that all of your ducks are in a row on the art, production capabilities, and finished craftsmanship for the piece. So why waste a good shirt? Why not produce one on a similar shirt, scrap shirt or even a pellon?

That’s because sometimes, you can’t sew out some random fabric and say you’ll get the same result on that super expensive Patagonia jacket or using puff foam on that New Era five panel cap. You have to use the same thing to predict the same results. Customers want to see the real deal before they commit to authorizing the magic word…”Go”!

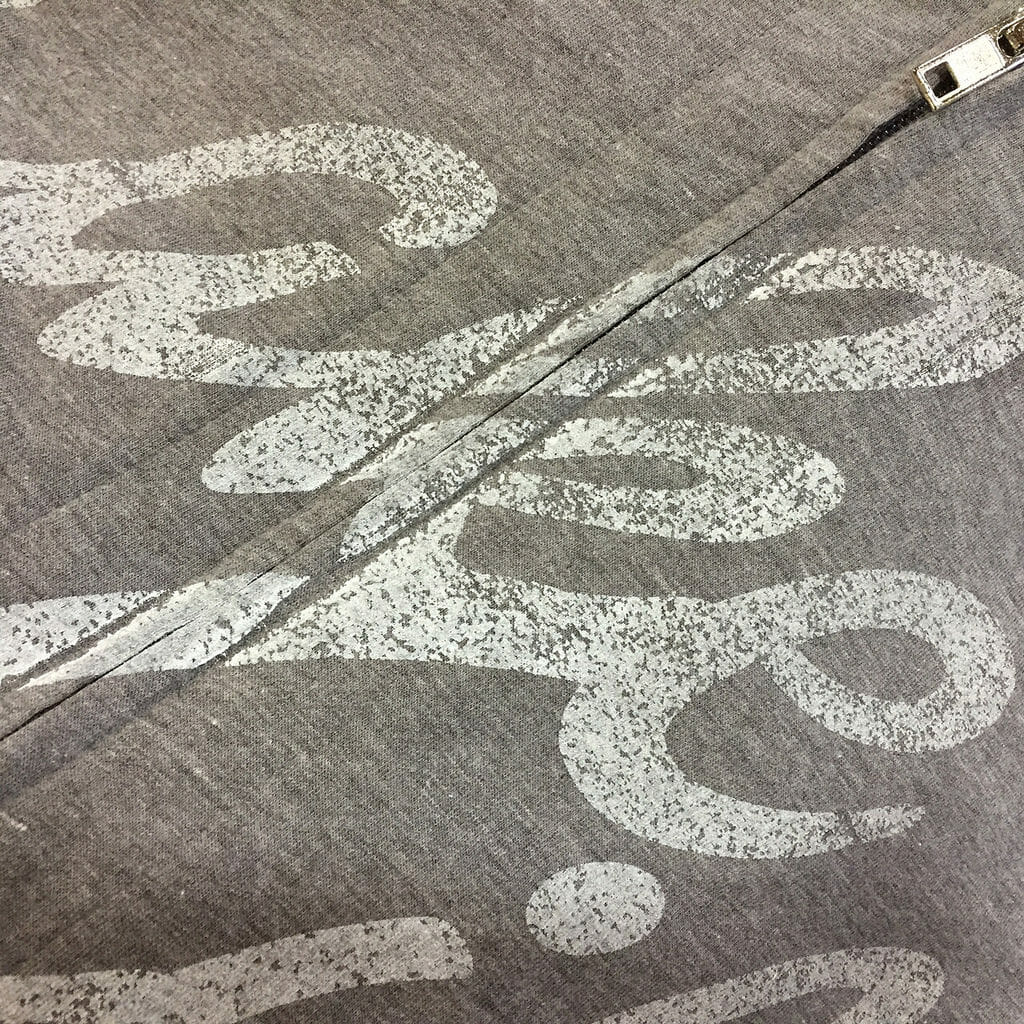

Just like for screen or digital printing, you’ll need to print the actual art on the actual shirt to get the actual results too. Will that art idea work on that tri-blend t-shirt? Will the zipper on the hoodie interfere with the legibility of the type? What will the hand be like if we print through high mesh with reduced down inks on a polyester shirt? Sometimes the only way to know is to do it.

Which is risky.

It’s risky because it might not work. Are you ok with that? Sure, there’s a lot of effort and debate over coffee regarding the design and the intentions, and you’ve done your homework to make sure that the design is separated, color corrected or digitized properly (uh, right?). However, until the rubber meets the road you won’t know for sure.

Because, you know. Money.

There’s the time invested in the set up, the cost of production for running a sample, plus the cost of the actual item. This will vary greatly depending on the art, production and the item to be decorated. So how comfortable are you with having financial conversations with your customers?

For most shops, not very. I’m in the same Facebook/LinkedIn groups as you, and collectively as an industry we’re all a bunch of scared mice. There are some exceptions, but for the most part our customers define what we are doing. It doesn’t have to be that way though.

Don’t you want control of your shop?

It’s much easier to develop a blanket policy that works for almost all situations, and then you can always deviate from that if need be. Which brings us to:

Sample Charges

Someone is going to pay for the sample. Is that someone your customer? Is it you? When do you decide in the sales process?

Hey, that’s what a policy is for! So you can discuss with your customer beforehand. Your rules define the situation. All you need to do then is to stick to your guns.

So let’s start with the basics. Art.

Samples are usually at the beginning of an order, and the first thing that needs to be handled is the art part of the deal. This could be that photograph that someone wants to put on a shirt and print digitally, a logo that someone wants embroidered on a jacket so they need some digitizing, or a new t-shirt merchandise line for that local band that’s blowing out everyone’s eardrums.

Pretend we are in your shop now. Do you charge to prep that photograph for digital printing, digitize that logo for embroidery, or develop that merchandise line for the band?

You should.

A lot of shops don’t…they see that as the loss leader to get the business. My thinking is that it all depends on who you are talking to and what they want. A great way to make the decision is writing that art charge procedure for your shop. Just define who gets charged and who doesn’t. It could be as simple as what price list to use when quoting the customer. It’s ok to have several different scenarios based on your customer annual spend. The new guy off the street doesn’t get treated the same way financially as the guy that’s stroking you big checks every week. Your fee structure for art and samples could be part of that pricing list.

A prepared policy that lists standard charges for developing art, prepping files and digitizing logos can work to your advantage. Don’t just make them up on the spot. Have a chart that you can send to customers via e-mail or hand them at the sales counter. You may already have this.

Next up are the run charges for samples.

Just like the art fees, you need to determine your stance on this. I’ve seen shops charge for samples based on a percentage of the final order, but most make it a flat rate based on the parameters of the job. Often embroidery shops will sew a free sew out on a scrap material, but if you want to risk that $150 Patagonia jacket, I would charge for the sample work. This at least weeds out that person who only wanted one jacket to begin with, and just wanted the logo sewn for free. For digital printing, a lot of shops will run a few shirts from a big order for samples, but if there isn’t one you need to charge for it. For screen-printing, most shops have a minimum run charge plus the cost of screens.

How much should you charge for all of that? Well, I’m not going to tell you. (Sorry, bub) That should be based on how you structure your pricing, your market, your competition, and how aggressive you want to be with your pricing schedule. What one shop charges shouldn’t be relevant to what another one charges…we all have different business scenarios and overhead.

However, this much I know. Customer service reps charge for stuff all the time that sales people give away for free. Why is that do you think? Don’t think so? Run an analysis in your system. I’ll bet I’m right…

Samples for Volume

Of course all the talk about money and fees goes right out the window when you interject the idea of samples for large orders.

Because this is “protect your butt territory.” An actual approved sample provides a lot of coverage.

For orders of larger size, cost or complexity, you want to do a pre-production proof that gets sent to the client to approve so they can see how it will look, feel and “exist” in the real world.

Especially if this was designed by some ad agency that doesn’t comprehend the realities of apparel decoration production. Hmmm, another mystery. Why don’t they ever ask if something is doable?

What’s a large order? Depends on the item and who you ask, but I would say any order that is financially big enough to make you worry. A thousand piece order may seem like a big order to some, and sort of mediocre to others. If you’ll be checking on this job multiple times during it’s production run to “see how it’s going”…then the fact that you are sweating the details enough to warrant eating the cost of a sample.

When it HAS TO be right. That’s the answer.

Sample Tips

First, place the sample order in the system as it’s own entity. Don’t just pull one or two shirts out of the box and run them and then shoot them over to the client in any old cavalier way.

If you make a Sample Order, you can schedule it, pull inventory to it, ship it, make notes about it, and generally keep track of it better. Place a second order in the system for the “real” order, and put it On Hold. Keep it On Hold until the client approves your sample run, then release it. If for some reason the client requires another sample, place another order in the system for that. Make everything unique, so it can be easily organized, tracked and notes entered about each one.

If there are any problems down the road a few months from now, being organized and having an avalanche of information regarding every step along the way will serve you tremendous advantages. Most customers don’t keep track. It pays to have all the answers.

Then run the sample on the same equipment you will be running the production order. This means you, Mr. Scheduler.

Yes, I know it’s a pain to set up that job just for three shirts, as that stops production for other “real” orders…but after that sample has been approved it’s going to need to run in real life. The best way to replicate the success from the pre-production sample is with the same equipment, staff and thinking that went into setting up the sample production run.

This means don’t screenprint that sample manually and then try to replicate it on the auto later. You aren’t saving any time when the auto can’t get the print to match. Even some embroidery machines have been known to have challenges replicating the same file on different production lines.

If you schedule things right, you can set the sample up for the last job of the day and run the job. After checking to make sure the shirts you send are absolutely perfect, ship them overnight for first thing delivery. If the client approves, you are already set up. If you can, just run other jobs around this until you get the word that way you don’t have to reset it up.

Inspection Required

It is absolutely imperative that at least one, but sometimes two, people review the shirts before you send them out. Get people that know what they are doing and have a good eye for detail. Sometimes getting the salesperson or customer service rep for the account involved is a good thing too, because they can state that they reviewed the shirts with sincerity. Look over the art instructions and make sure you are using the right thread or ink and that it is exactly placed on the shirt as requested. Check for any dirt, smudges, stains, rips, hems, buttons loose, or any defects with the shirt. This is especially true when printing something for a new client, or a huge order.

So this means if there’s a small pinhole in the screen and there’s a little green dot down below the image that you didn’t notice, but your client does, it’s going to be a huge issue.

Because that mistake on the sample is going to plant the seed in the client’s mind that every single one of the shirts for the production order is going to have the same problem.

Because even after you swear up and down that the little green dot won’t be there during the production run, even if you actually print another sample, that customer is going to be looking for it. For the whole production run. They may even have teams of people looking for it.

I would. Wouldn’t you? These days, there’s very little trust floating along out there.

A much better plan is to go over a sample with a fine tooth comb and find those problems and alleviate them, and even redo your production sample if need be, than go through that. You would rather be late and perfect than on time and wrong.

Of course the alternate version of the sample defect is true also. Send them the perfect sample, and they will think that every single one of the production shirts will look exactly like what you sent them. They won’t have the A team culling through every shirt in the order looking for a problem, because it doesn’t exist.

Samples are about alleviating doubt, not causing it. Don’t stoke the fires of hell.

Ask This One Question

If a customer asks you to decorate on some funky thing you’ve never seen before prior to placing a “big” order, there’s one question that I always ask.

“Is it ok to ruin one to find out if it will work?”

We get asked to decorate all sorts of products, garments and stuff constantly. Most of the stuff handed to us we might have a good idea if we can do it. But some of these… The only way to know is to send it down the dryer or try to hoop it. A majority of the time, I just want to see if the ink will stick or if the product will survive production. We’ll worry about the art later.

That question has saved me a lot of time and trouble over the years. If the answer is “Yes, go ahead”, then they know how difficult a task it might be to decorate. The ones that say “No, that’s too expensive of an item to sample just one.” are usually the ones that try to stick to you later when they don’t like how it turned out.

So when someone asks you to brand a soccer ball, plastic quilted metallic tote bag, dance leotards, yoga pants, blow-up astronaut dolls, nautical themed captain hats, ice cream machines, cork bulletin boards, ipads, cashmere scarves, swimming pool covers *, or other things they pull out of thin air what are you going to say?

(*all things we’ve decorated or sampled in the past few years)

The Importance of Notes

The reason samples are printed doesn’t much matter sometimes but getting to the next step, the production run, always will. Hopefully your team has done a good job and the sample went off without a hitch. The client thinks you are a genius, and can’t wait to hand over all of their work to you in the future.

So now you have to produce the main Production Work Order. If the job isn’t still ready to go on a machine, hopefully you took good notes so you can get it up and running quickly. Here’s where the importance of using the same production team as the sample really kicks in.

Your job now is to match the sample you sent to the customer EXACTLY. (er, you kept one right?) If it doesn’t match exactly whatever you do, don’t run it.

Here’s where having a set of notes, essentially the production sample recipe, with the actual production sample could save you a bunch of time. Imagine how nice it would be to have every detail and tweak needed to replicate the job, right at your fingertips when you need them. Well, unless you jot that stuff down when you set the sample up, you’ll be cursing under your breath wishing you did.

Some shops use a great looking form that asks for production details, others just jot it down on some masking tape and stick it to the sample shirt. It doesn’t have to be overly complicated, but it needs to be accessible. If you use a computer system for design information, typing it in there so the next time you run the job a month later it will print out with the order will work too.

So now you are running the job, please make sure that your crew is constantly referencing the sample shirt to ensure that nothing but clones are coming off your equipment.

The perfection you are seeking should be sickening if it was a sci-fi movie. Every one is exactly the same! Ahhhh! Now your shop can practice the mad scientist laugh all the way to the bank. Muhahahahaha!

So to recap here is the baker’s dozen of Secret Shop Strategies for Shirt Sampling Success:

- Have a prepared list of sample rules and charges.

- Always charge.

- Unless it makes sense not too. It’s up to you to decide when.

- Staff is trained to know the difference. Ask questions if unsure.

- Sample orders go in the system as their own unique Work Order.

- Main production orders are entered and put On Hold until the sample is approved.

- Use the same equipment that the real job will be used to produce the sample.

- Samples going to clients have to be perfect. PERFECT.

- Make sure you produce one for yourself for comparison purposes.

- Record the recipe for success on how the sample was achieved.

- Production run shirts should match exactly to the sample.

- Compare often during production. Not just the first strike off. Try to find a problem.

- Bonus: Practice your mad scientist laugh while depositing huge checks in the bank.

“Success is the result of perfection, hard work, learning from failure, loyalty, and persistence.” – Colin Powell

“Pleasure in the job puts perfection in the work.” – Aristotle