Psssst. Hey you. Yeah…you. The shop owner sitting there in your chair at 7:42 pm at night still thinking about work. Your day was really crazy wasn’t it? Lots of darting around the shop checking on things, occasionally lending a hand to a staff member, getting interrupted seventy-five times an hour with questions that just can’t wait, and at the end of the day you are still always worried about tomorrow. A lot has changed since you first opened your doors way back when. Your company has grown and prospered, but it still isn’t where you want it to be. Can you ever truly relax? If only…

If only you had better people. When you think about your staff that you’ve hired, there’s only really a few rock stars. Sure, you’ve hired some competent people, but you know deep down most of your staff are just there for a paycheck. Do they really have your back? How many of your challenges that you are constantly working on circle back to people issues? Are you just “working with what you have” or are you pushing your staff by raising the bar with higher expectations? Need a better team? Get rid of the deadwood and revert back to the old adage “Hire for Attitude, Train for Skill”. Don’t put up with incompetence, apathy, or laziness. Set clear expectations for excellence. Think in terms of sports, and try to get the best players on the field for your team. Let someone else have the junior varsity caliber people. It’s ok if you let your deadwood workers find the opportunity to discover a new career. Maybe they will find their true calling somewhere else.

Also, look to your company leadership to drive the culture change. They are the ones that are putting up with the complacency. Why? Push down the change you want by motivating them to get on board with your vision. Whatever you want your company to be, you first need to clearly communicate that to everyone there and then drive that home at every opportunity. Reward positive behavior, even if it’s a simple thank you or public acknowledgement that someone performed the way they should. It’s tough sledding sometimes, but stay the course.

If only you had more money coming in. Times are tough, and it’s hard to compete. Sometimes raising prices can hurt more than help. So how do you find more money in the operations you are already doing? Simple. One way is to take a close look at starting a sustainability program in your shop. Reduce, Reuse, Recycle. Sometimes the money you are looking for is already in your shop and you just step over it every day chasing a dollar down the road. Pull together the staff from your company that can contribute and start a sustainability committee. Tackle projects with easy wins that will pay-out first such as lowering your energy costs, or looking at your purchasing decisions. Get a free energy audit from your local utility, and based on their report plan to make a few changes. Examine how you are buying your consumables, and see if there are better alternatives that are less expensive, perform better, or sometimes both. Just because you’ve always used one brand of ink or bought your packing tape from a particular store doesn’t mean you have to do it that way forever. Is there better equipment in the marketplace that can operate more efficiently? There always is a better way. SGIA has a great Peer to Peer help group that you can join to learn how to tackle sustainability challenges in your shop. Click here and get signed up.

Are you in the camp that thinks a sustainability program won’t save you money, or is just a bunch of tree-hugging hubaloo? Think what you want, but in three years I’ve reduced the cost per impression for Visual Impressions by five cents an impression. How many impressions did you print and embroider last year? Do the math. There wasn’t a magic bullet to that effort, as it was accomplished with the help of a fantastic staff and a lot of hard work. That savings didn’t happen overnight. We tried and failed many times over with some different ideas, and actually are still working on a few more opportunities today. Get your sustainability committee together and think about how you can start. What would you do with an extra duffel bag full of dollar bills?

If only you were more organized. Got scheduling or workflow problems? Jobs are always late? It may come down to the organizational skills of your production management team or it could be the procedures you have established in your shop. Sometimes there needs to be changes to solve a problem, but we are reluctant to go about that change as it’s scary. What’s scarier is doing nothing, and just to keep eating the crap sandwich every day. One of Steven Covey’s famous 7 Habits of Highly Effective People is “Begin with the end in mind”. This is the perfect statement for a production environment. What do you want to achieve? Focus on that and work backwards to see what you need to do.

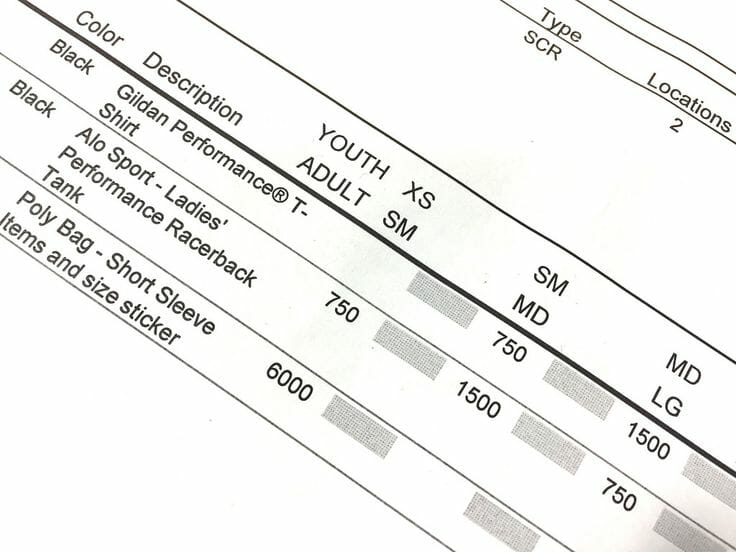

For example, let’s say you have a 5,000 piece two location job that has to ship next Friday. When would you need to start printing? Just run the math. 5,000 pieces x 2 locations = 10,000 . 10,000 / (average impressions per hour for your press) = X number of hours needed. From there, that will give you the day to start printing. Do you need to put this up on more than one press? Work overtime on Saturday? Thinking it through before you start the job helps you with scheduling, and also pricing. Your shop should have a rule that the goods and approved art will need to be in place one business day before the start printing day. This gives you time to burn your screens, check in the inventory in receiving, and stage the job. This scenario should play out with all of the jobs on your schedule. If you are using a shop operating system, your team should be able to review all active jobs in the system and look for potential problems. The discipline should be that the account representative or salesperson will move the job out without being asked when the art isn’t approved or the goods aren’t delivered on time. It’s a team effort, and if you do it correctly you can manage a hectic schedule without having a production meeting.

The great thing about looking ahead, especially if you train your front office staff, is that they can state to the customer what’s needed and set the expectations from the beginning of the order. If the puzzle pieces don’t fit right, then they can be discussing the need for more time on the job, extra money to pay for overtime, or even starting the discussion about expedited freight at the beginning of the order instead of the day it’s supposed to ship. Getting out in front of the production discussion really helps alleviate some of the pressure with your customers, as not all of the cards you are dealt can be controlled.

If only you had more time. Sometimes it sucks that there’s only twenty-four hours in a day. However, in our industry time usually works against us when we have an overloaded schedule or a big job to fill. You can get more time though. Most shops have unused capacity as they don’t have a second production shift. Those machines that sit idle all night long could double your throughput capacity. You just have to find the workers and responsible management to run them. (I didn’t say it would be easy!)

Another option is to partner with another shop and outsource orders you may have a hard time filling. While you’ll make less money obviously, contracting the job out could be the solution to preventing a huge overtime labor hit, missing a ship date and disappointing your customer, or other doomsday scenarios. Be careful though, and only job out an order to someone that you trust and have a good relationship with as if anything goes wrong, you will still be on the hook for the order.

If you are a small one or two person shop, you may find yourself doing sales or art chores when you need to be printing or running an embroidery machine. You can’t be two places at once, so welcome to ten to fifteen hour days. This is where you should start seriously looking at hiring and training more people to help you. You can’t grow your business if you can’t be out there pulling new customers into your shop. Even a part timer could provide huge benefits. If you are seriously considering this, there are many good avenues in which to find great help. One inspiring resource I’ve found is working with a local governmental agency that finds and trains jobs for people that have been laid-off or are having trouble finding employment. Here in Milwaukee this is run by the Wisconsin Department of Vocational Rehabilitation, but in your area this could be something different. They pay the employee’s wages for 90 days while you train them in the job. After 90 days you get to decide if they are acceptable to hire as a full time worker for your company. If the adage “Hire for Attitude, Train for Skill” means anything, these people all have the attitude part down. The “Train for Skill” part is up to you.

If only you had more resources. Are you kidding me? The decorated apparel industry is one of the best fields that try’s very hard to look after its own. There are great industry publications such as Impressions, Printwear, Wearables, Images, and the SGIA Textile Journal that all have wonderfully written and informative articles on relevant topics. Do you subscribe and read these expert-level articles? Backing this up every year are the great trade shows where you can take a class to learn a new skill or discuss a challenge with an entirely new vendor stream. There are also many wonderful LinkedIn, Website and Facebook forum groups where printers hang out, chat and gossip. In these forums, if something isn’t working or someone gets burned by a supplier, it gets shouted down from the mountaintop very quickly. Do you participate in these? You should. Build your network!

Also, one often untapped gold mine in the industry are sales reps from your suppliers. While these folks are always interested in getting you to use their products, quite often they can back it up as they ran businesses or production for other companies. Not to mention, they are traveling and visiting other shops constantly. They see what works and what doesn’t. Try reaching out to your vendor support team next time you have a challenge. I think that you will be surprised in that the answer is under your nose all along.

If only your customers made it easier. Customers. We love them and we hate them sometimes simultaneously. I guess it all depends on their level of competency too. Do they know what they want and can they communicate that effectively to you? Sometimes you have to help them. These days when more and more online t-shirt platforms are popping up everywhere and snagging a lot of the business, that pain in the butt hand-holding you hate could be the value added feature that keeps your orders in the door. You should revel in the fact that you can work with people face to face and walk them through the order, taking their fears away and making the process easier. Sell that. You can provide expert level recommendations on what shirt is softer a Hanes Nano or an American Apparel. “Here, feel the shirt and compare.” There isn’t an iPad app for that. The front end work that you put in to make your customers comfortable and ordering easier will pay off in big dividends when they can’t get that same level of service somewhere else. Not all customers are so price driven that they will abandon you to save a penny. There are huge swaths of customers that will pay more for great customer service, quality decoration and the knowledge that they are being taken care of with a first class shop. First, you have to build that. Read how to build a Customer Service Success Kit by clicking here.

If only you were prettier. I can’t help you with that…but that’s why we have Photoshop. Seriously though, the expectation of being a professional is that you do things the correct way. This can also apply to you on a personal level. Talking heads in the media keep saying to get plenty of rest, eat right, drink plenty of water, exercise and so forth? They’re right. Just like your equipment out on your shop floor, your body is a machine. Do you have a preventative maintenance program going for your capital investments in your shop? Shouldn’t you do the same for yourself? I know it’s tough. There’s only so much time in the day, but this is a puzzle you have to solve. Make it fun. Include your family. Stop watching American Idol, playing Candy Crush, chatting on Facebook, or whatever excuse you have and just do it. If you think about it you do have the time, it just how you prioritize it that’s the problem. If you feel good and have a great attitude every day, that translates down to your staff. Being positive, full of energy and healthier can give your staff the expectation on how they should model their lives as well. As the boss, they look up to you. People are always watching.

I talk or correspond with a lot of shop owners, and trust me, everyone has just about the same set of problems. People, communication, market pressure, and production. Shops that get it, are actively working to improve these every day. Struggling shops tend to have a more laid back attitude on one or all of these points. Maybe it’s the personality of the owner, maybe it’s a skill set that has to be learned. The trick of course, is to get out in front of these challenges and bang away at them constantly. The hard part is starting. If only more people would do that.