Every single day in your shop you are losing money. Did you know that even the best and most profitable shops could be making more?

What am I talking about?

Downtime.

It is simple. The more shirts you decorate a day, the bigger the opportunity for your shop to make money.

After you read this article I want you to go out onto your production floor and stand there. Simply watch people work.

They are busy hustling around the shop doing tasks. It may even look like someone just kicked over an anthill, with everyone scurrying around doing things.

Look Closer

But take a look closer. The only thing that matters is completed orders.

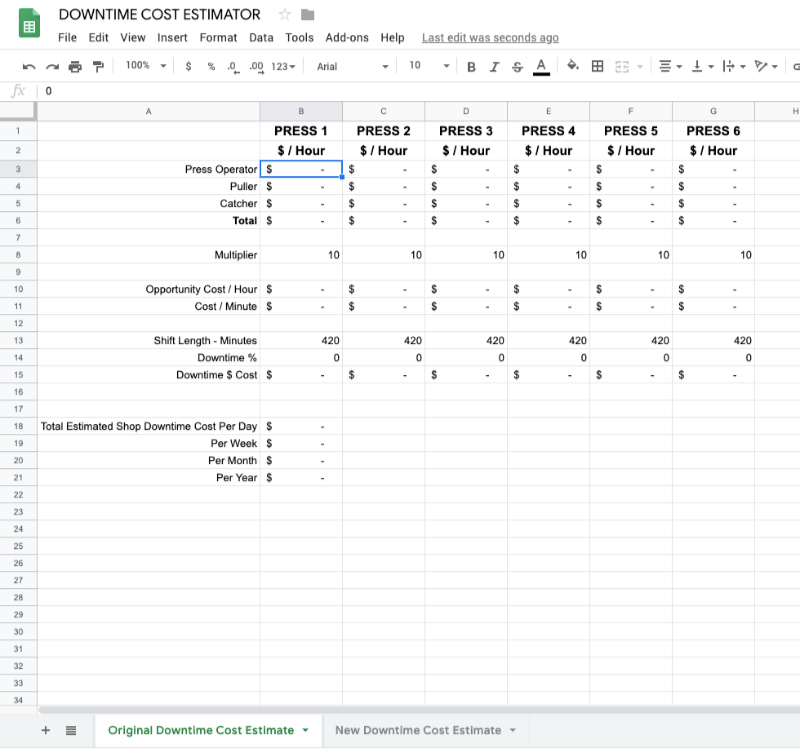

I want you to consider how much money each of your production machines should be making you an hour. $300? $500? $1000?

What is the valuation on each of your machines per hour? Don’t use my numbers, use yours. What is the financial opportunity for you every hour if that machine continually cranks out work?

Put a dollar amount on that.

Downtime is Cancer

For the sake of argument, let’s say that you valued one screenprinting automatic press at $300 per hour. I like to use that in discussions as it breaks down into $5 per minute.

If you walked out onto your shop floor and simply watched your crew work, for every minute that ticks by and you are not printing a shirt, go ahead and break out your wallet and throw a sawbuck onto the floor.

At the end of the shift, how many $5 bills would there be at your feet? Just how big of a stack do you think that might be?

My Gift To You

If you really want to dig into what this is costing you, I’ve prepared an easy to use spreadsheet for doing this challenge valuation.

Also, here’s a video on how to use the spreadsheet in your shop to calculate how much your downtime is really costing you. Every day. Each week. Per month. And yes, annually.

Next Steps

The reason for this blog is to let you know that I have a new online course that is dedicated to helping you with this challenge. It’s called the “6 Steps to Kill Your Production Downtime”.

In the online course are easy to follow exercises and pro-tips to solve this problem. The Downtime Cost Estimator and the video above are one of the sections from the course.

I want you to use them in your shop for free. Right now.

This will help you understand the financial magnitude of the challenge that your shop faces every day. It’s more expensive than you might think.

After you have calculated the annual cost of this challenge for your shop, using your own shop’s math, then you might be a good fit to buy the online course.

“6 Steps to Kill Your Production Downtime”

All you need to do is click the button below and get signed up and buy the lessons. In the course are video guides that explain and walk you through each step. Also included are all of the worksheets and templates to use for your shop, as well as the Production Logs and Production Dashboard system to use to calculate your downtime correctly.

Everything you need is included.

So, if your shop needs some help with controlling excessive downtime and pushing for better efficiency and profitability, this is the online course for you.

“Lack of money is the root of all evil.” – George Bernard Shaw

“Don’t let making a living prevent you from making a life.” – John Wooden

“Friendship is like money, easier made than kept.” – Samuel Butler