Profit is not a dirty word. For businesses, it is good to be profitable.

But for many companies in this industry, (yours perhaps?) the owners and leaders do not know how to calculate profit, how to increase profit, or even how to think about profit.

This conversation is all too familiar in this industry:

Me: “How are your sales this year so far? Are you hitting your goals?”

Shop Owner: “We’re doing great! We’re on track to have our best sales ever!”

Me: “That’s incredible! What’s the profit on that?”

Shop Owner: “What do you mean?”

Me: “Bottom line, how much money have you made?”

Shop Owner: “Oh, we don’t know that yet. We’re waiting until the end of the year to determine how much money we’ve made.”

Me: “Huh? Why don’t you know this?”

How To Calculate Profit

Yes, I know you know this. Or are supposed to know this. Maybe you want to know this.

Here it is anyway.

There are three types of profit margins in a business.

- Gross – equals the total revenue minus the cost of goods sold.

- Operating – equals the total revenue minus the cost of goods sold and operating expenses.

- Net – equals the total revenue minus the cost of goods sold, operating expenses, interest, taxes, debt repayments, and any other outgoing expenditures.

First, determine your total revenue. That is all of your sales.

Then, subtract your costs (see above for Gross, Operating, or Net). What is left is profit.

Revenue – Costs = Profit

If you divide the profit number by the revenue number you will get your profit margin. Multiplying that profit margin number by 100 will give you the profit margin percentage.

For example:

Total Revenue = $536,453.27

Total Costs = $401,792.45

$536,453.27 – $401,792.45 = $134,660.82 in total profit.

$134,660.82/$536,453.27 = 0.251

0.251 x 100 = 25.1% profit

Question For You

These numbers in the example above could be per week, per month, per quarter, or per year. They are just numbers I’m using to explain.

My question for you is do you know yours? Right now?

Many of the shops that I’m talking to when they reach out for help do not know these numbers. Instead, I get fumbling excuses as to why they don’t have them.

Topline sales (revenue) is one thing. But the bottom line sales is where your focus should be. As my friend Mark Coudray says, “Top-line sales are vanity, bottom-line sales are sanity.”

Increasing your bottom line profit is more than just what it costs you to operate. Growing that is all about operating more efficiently.

How to Find More Profit

There are three easy ways to increase profit.

- Raise Prices

- Lower Costs

- Increase Efficiency

For this article, we’re going to focus on number three. Increasing efficiency.

Simply put, this is getting more things produced quicker, easier, and with less work. The more jobs you can produce a day with the same basic overhead costs, the cheaper it is for you to run your company.

Hence, more profit.

Question For You

So, are you tracking this? Do you know your numbers?

Yeah, I know. It’s that math stuff again. Not as fun as decorating shirts, or closing a deal with a customer…but just as crucial.

In fact, many people operating businesses in this industry are simply out of touch with what is really going on in their business. For example, how did you build your pricing matrix?

For a lot of shops, it is based on what “other people around me charge” and not on what it actually costs to run the business. What if everyone around you is unprofitable? Guess what? Now, you are too.

If that sounds like you, here’s a book you should read.

Everything Needs A Number

Let’s get back to that efficiency thing. For any process in your shop, you need to know two things:

- Capacity – how much are we capable of doing in one shift.

- Velocity – how fast are we, on average, able to do something.

This is in all aspects of the work your team cranks out every day. This could be with orders entered, or screens burned, or boxes received, or jobs printed or embroidered. It doesn’t matter.

For those tasks, what is either the capacity or the velocity? Do you know those numbers?

If you do, great. But if the answer is no, start measuring.

Once you have established these and everyone agrees that they are true, the next step is to improve them.

You Can’t Manage What You Don’t Measure

Getting your numbers is the hard part. For starters, it has to be accurate. You don’t want to be basing business decisions on guesses, right?

It also has to be easy to acquire. When anything is labor-intensive for tracking, people quit doing it. The simpler the better.

This is why we’ve developed the Production Tracker system.

If you want to increase the profit in your business by developing better efficiencies, you first have to establish how to collect your data.

Production Tracker allows your crews to easily enter their data with a few steps. It works on any phone, tablet, or device.

Graphing Your Data

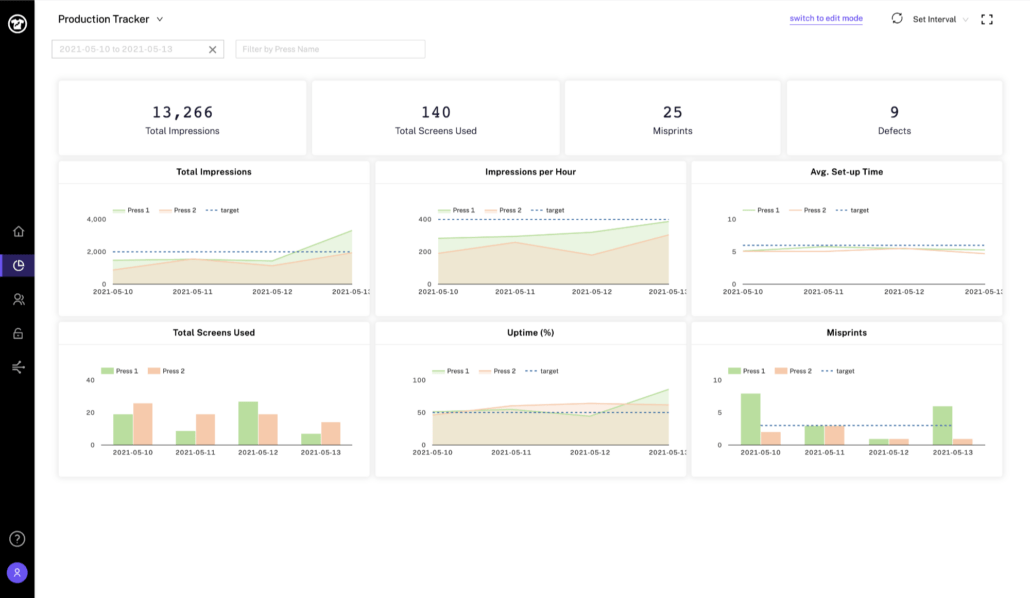

What’s great about this system is that it allows you to automatically graph your production data so your production management team can elevate problem-solving faster.

The numbers that flow into the system are automatically graphed on a dashboard that is URL-based. You can mount a flat-screen monitor on a wall and sync this graph.

Imagine the impact of having your shop’s production numbers updated every fifteen minutes and available for your leaders and crew to view!

In the example graph above, take a look at the KPIs listed. How could you use this in your shop?

For instance, the shop has set a goal of printing at a rate of 400 impressions per hour. This is easily achievable on an automatic screen printing press with a full crew of trained staff.

But in this case, they are underperforming. Sure, with the two automatic presses, they have produced over 13,000 units in four days, but how many more orders could they have printed if they were meeting their production speed goals?

This is a lost profit opportunity.

The ramifications of this could be a production schedule that isn’t on time. Maybe extra shipping charges to get the goods to the destinations on time. Are customers getting irritated that their orders are late? That’s not good.

Getting accurate, and more important, timely numbers allow your production management team to insert themselves and solve these challenges.

Your Next Step

Here’s what you need to do. Click the button below and schedule a time with the Production Tracker team to get you onboarded with a demo.

The basic plan includes one administrator and up to thirty operators for your shop for $50 a month. That’s nowhere near what this is costing you in lost profit even for an afternoon.

“Proft in business comes from repeat customers, customers that boast about your product or service, and that brings friends with them.” – W. Edwards Deming

“A great merchant delivers both joy and profit. Then profit gets reinvested in more joy.” – Andy Dunn

“You don’t have to be a mathematician to have a feel for numbers.” – John Forbes Nash Jr

Help Support This Blog

If you like this blog and would like to support it, you can:

- Buy a book.

- Share this blog on your social media.

- Join Shirt Lab Tribe.

- Subscribe to the Success Stories podcast.

- Watch and like an episode on the Jerzees Adventures in Apparel Decorating YouTube series.

Thanks!