I have a conversation about press workflow regularly. Hey, that is what I do. Everyone wants to learn how to achieve more production throughput with less time, cost, but still achieve higher quality results. For today, I want to focus on one thing.

Running automatic screen printing presses for maximum productivity and profit.

In that nearly weekly conversation, the shop owner usually talks about how they can’t afford to run the automatic press with a full crew. And for the sake of this article, let’s assume that the shop has plenty of work, so there isn’t an issue of the production schedule being light due to sales. Let’s also state that a full crew is composed of:

- Automatic Press Operator

- Automatic Press Unloader (or Puller)

- Automatic Press Catcher (or Quality Control)

The reason why this matters is that this same owner usually wants more production. They might want to add a second shift or even buy another press. Nothing wrong with that. But those ideas can take some time and money to develop. And, actually may be unnecessary.

Instead, I’d like to show a side-by-side comparison of why running that press crew a person short may have a bigger impact than you have thought about.

Starter Numbers

Because the equipment, people, types of work, consumables, geographic location, and other conditions may vary from shop to shop, I cannot guess the exact numbers matching your shop’s results.

I challenge you to pull your own data. This is important, and using your specific data for what happens on your production floor is key to understanding and improving your workflow and cost optimization.

That being said, we are going to use these data points and terms for comparison:

- Automatic Press Operator Pay = $20 per hour

- Automatic Press Puller = $15 per hour

- Automatic Press Catcher = $15 per hour

- For this article, we are only looking at the labor rate as the highlighted factor. Let’s keep things simple. The reason is that many shops state that they can’t add another person as that will be too much labor cost for the extra production gained. So, let’s focus on that.

- An “Impression” is a unit of work. It is not the number of squeegee strokes or colors. A 100-piece order with a front and back location = 200 impressions.

- The press speed is measured by how many impressions per hour are achieved. These are printed garments on the table, not what is shown on the press control display.

- Set-up time is measured from the moment you start working on a setup until it is approved to run. You want to know how many minutes per screen it takes to accomplish that task. This is expressed as “minutes per screen.” A three-color job that took fifteen minutes to set up would be “five minutes per screen.”

- The example shop has one shift. They start at 7:00 AM and work until 3:00 PM. There is a paid 15-minute break at 10:00 AM and 2:00 PM, with a thirty-minute unpaid lunch at noon. There is a total of 420 minutes available for production.

- For this example, everything the press crew needs is staged and ready. We are only looking at production times here, not other challenges. As we all know, crazy things can happen in production. That stuff is a different article.

- Also, for the sake of discussion, every order set up and printed is completely different, but we will say they are all three-color, front-only jobs to make it less about what we are printing. We are only looking at the average times here, so note that the individual differences between orders can have an effect on the output. (For example, hoodies vs. tees, or adult vs. youth)

- Each different job is a 50-piece order. This shop is selling them for $20 a shirt. Therefore each job completed is $1000 worth of production completed per day.

Example Shop Press One: Minimal Print Crew

For this example, let’s look at the daily numbers with a minimal print crew of two people. For this, let’s say they are running an automatic screenprinting press but only using a Press Operator and a Catcher. This is very common.

If this is your shop, please gather your data and plug in your numbers. Yours may be better, or they may be worse. It is important to know.

- Average screen setup time = 7.5 minutes per screen

- Average print production speed = 150 impressions per hour

- Average transition time between jobs = 10 minutes.

- Each order is the same: three color front on 50 pieces.

So how does the day shake out for them with these example orders?

The crew arrives at 7:00 am and starts setting up the first job. By my calculations, accounting for breaks and lunch they will be able to finish eight jobs in that span of time. The three screens will take about 22 minutes to register. It will take twenty minutes to screen print all fifty shirts. Ultimately, it will take ten minutes to break down the current order and transition to the next. The total time for each job is 52 minutes.

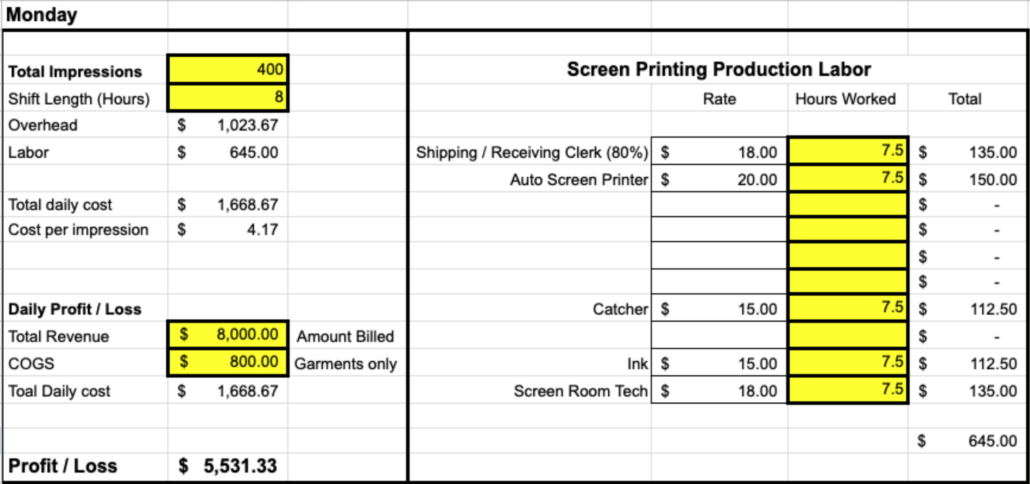

Just looking at labor costs, the printer is paid $20 per hour, and the catcher, $15, for a total of $35 per hour. We also want to throw in a Shipping/Receiving Clerk at $18 per hour and some support help for the press with an Ink person at $15 per hour and a Screen Room Tech at $18 per hour. This brings the production floor costs to a total of $86 per hour total. If the shop pays for their breaks but not their lunch, they owe them for 7.5 hours worked.

$86 x 7.5 = $645.00.

The crew completed eight fifty-piece jobs for a total of 400 units printed. The total daily cost with overhead ($1,023.67) and the labor added together is $1,668.67. Divide the two together, and the cost per impression for each print was $4.17.

$1,668.67 / 400 = $4.17

Example Shop Press Two: Full Production Crew

Let’s compare it to another press crew running the exact same work. However, in this scenario, they use an “Unloader” on the press to pull off the shirts from the automatic screen printing press and help with the setup and breakdown of the jobs. This is the press operator’s main assistant, and usually, one that is being trained to run the press as well.

If this is your shop, please gather your data and plug in your numbers. Yours may be better, or they may be worse. It is important to know.

- Average screen setup time = 5 minutes per screen

- Average print production speed = 400 impressions per hour

- Average transition time between jobs = 6 minutes.

- Each order is the same: three color front on 50 pieces.

As the crew has an extra pair of hands, some of the times have decreased or increased depending on the task. So how does the day shake out for them with these example orders?

The crew arrives at 7:00 am and starts setting up the first job. By my calculations, accounting for breaks and lunch they will be able to finish thirteen jobs in that span of time. The three screens will take about 15 minutes to register. It will take about 7 minutes to screen print all fifty shirts. Ultimately, it will take 6 minutes to break down the current order and transition to the next. The total time for each job is 28 minutes, which is 53.8% faster, just by adding one helper.

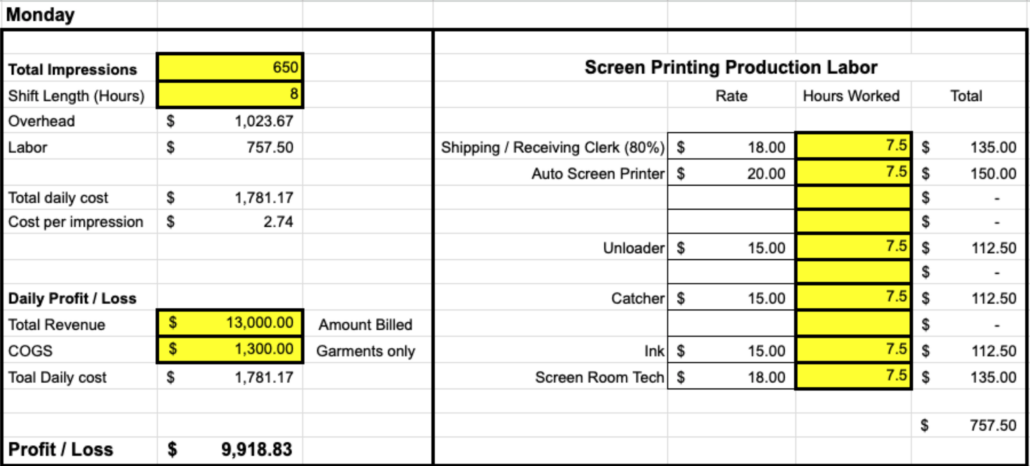

Just looking at labor costs, the printer is paid $20 per hour, the puller is paid $15, and the catcher $15, for a total of $50 per hour. We also want to throw in a Shipping/Receiving Clerk at $18 per hour and some support help for the press with an Ink person at $15 per hour and a Screen Room Tech at $18 per hour. This brings the production floor costs to a total of $101 per hour total. If the shop pays for their breaks but not their lunch, they owe them for 7.5 hours worked.

$101 x 7.5 = $757.50.

The crew completed thirteen fifty-piece jobs for a total of 650 units printed. The total daily cost with overhead ($1,023.67) and the labor added together is $1,6781.17. Divide the two together, and the cost per impression for each print was $2.74.

$1,781.17 / 650 = $2.74

Wait A Minute

Hold on there. I thought there was going to be a savings? Adding an extra person increased the production costs per hour, to $101.

But what was the actual cost per imprint savings?

$4.17 – $2.74 = $1.43

Wouldn’t you want to save $1.43 every time you print something?

But Wait, There’s More!

Yes, of course, there was more labor per hour. That third employee on the press needs to be paid. But wait! There’s more.

The minimal Press One crew could only complete $8,000 worth of work in the shift. (8 jobs x $1,000 per order). The maximum Press Two crew was able to complete $13,000 worth of work in that same time (13 jobs x $1,000 per order)

I used the Daily Cost Spreadsheet that was featured recently on this blog space. You can review that here. I modified it slightly to account for fewer production staff and management so that this could reflect using one press for production more closely.

If we use $2 per shirt as the cost of the garments and $1,023.67 as the daily overhead rate, the shop with the minimal production team makes $5,531.33 daily running a two-person automatic team.

Here’s Where The Winning Takes Place

Remember, we are trying to compare apples to apples here. The only thing that has changed is that we added one more person, the screen printing press unloader, at $15 per hour. Everything else is exactly the same.

Therefore, if you look at the increase in labor in isolation, it appears that the extra money added to the daily labor total may not be worth it. If that is the only metric you are reviewing, bumping the cost per hour to $101 may not be the money you want to spend.

However, that extra help added five more completed jobs to the daily production. The max Press Two crew had a daily profit of $9,918.83 vs. the min Press One crew’s day of $5,531.33.

That is a $4,387.50 positive difference.

To put it another way, for a $112.50 investment (the Unloader’s daily pay), they made a 3,800% increase on that extra labor.

You tell me if you think that it is worth it. HOMEWORK – plug in your numbers. Try this for yourself with your own work in your shop and see what you find.

“The big problems are where people don’t realize they have one in the first place.” – W. Edwards Deming

“If you can’t describe what you are doing as a process you don’t know what you are doing.” – W. Edwards Deming

“A bad system will beat a good person every time.” – W. Edwards Deming

Help Support This Blog

While I may be goofing around with AI for some projects, this blog and its contents have been created by me, Marshall Atkinson.

Why am I writing this? To remind you, dear reader, these words are backed by a real person. With experience, flaws, successes, and failures… That’s where growth and learning happen. By putting in the work.

If you are reading this and it is not on my website, it has been stolen without my permission by some autobot. Please report this to me and/or publicly out the website that hijacked it. And if you are trying to copy and use it without my permission, you are stealing. Didn’t your mama teach you better?

If you like this blog and would like to support it, you can:

- Buy a book.

- Share this blog on your social media.

- Join Shirt Lab Tribe.

- Subscribe to the Success Stories podcast.

- Watch and like an episode on the Jerzees Adventures in Apparel Decorating YouTube series.

- Get signed up for the new Production Tracker app.

Also, my basic elevator pitch to you is that I help with “Clarifying effective change.” If you are dissatisfied with your business’s current results, maybe I can help.

Please schedule a discovery call here if you want to learn more.

Thanks!

Marshall Atkinson also shares exclusive blog content at Supacolor.com. Supacolor makes The World’s Best Heat Transfer and provides tips, inspiration, and other resources designed to empower professional garment printers.