Maverick from the movie Top Gun famously said, “I feel the need for speed.”

Now more than ever, this is exactly what your shop needs. Speed.

Speed is a competitive advantage. We live in a fast-food lane, Amazon ships and it arrives the same day, zero-patience world.

Right now, what is your average turn time in your shop for your average type order? Do you even know? Have you actually calculated this, or is it just your “gut feeling?”

Remember, you can’t manage what you don’t measure.

Speed doesn’t happen by accident. Also, we all know what happens if we don’t have the processes and procedures in place when we need to ramp up speed. Quality goes down. Mistakes go up. Employees are frustrated. Ownership and/or management sees a spike in their blood pressure and starts to bark orders like a dog.

Yikes.

But it doesn’t have to be that way. This article is dedicated to helping you increase the horsepower of your shop and build a racing engine that can serve you and your customers better.

Step One: Where the Real Speed Starts

You might say that you need better equipment. Or faster computers. Maybe automation in the process somewhere. Those all are ideas that could help…but the number one place to start looking at speed is with one idea.

Information.

Were you expecting that? Long-time readers of this blog probably guessed it, but with all of my work in shops that I’ve run and also working with clients, this is the number one thing that can make a tremendous impact on the overall speed of your business.

Why is that?

Because missing information stops the process.

Wrong information produces mistakes and errors. Which usually means doing something over.

Not understanding information creates confusion. Indecisiveness slows things down to a crawl.

Good news! Change is within your grasp.

Implement An Information Audit

Want to understand how information impacts your business? Do some investigating and dig in on how you handle information in everything you do.

Start with your information funnel. This is your interaction with your customers at the beginning of the ordering process. Are you getting 100% of the correct information BEFORE an order is created in your system?

Trust me, I’ve seen plenty of orders sitting produced on the shipping dock while someone was trying to get the right ship-to address. This never should have happened.

How many times have your art staff had to make a change to something because a detail or instruction was left off the creative brief from the sales team?

Has your embroidery production crew had to choose a thread color for a tonal design and guessed wrong? Maybe your printing team didn’t understand the placement on the back of some hoodies and the customer was upset because the imprint was too low or too high?

How information flows to your team members is crucial to their decision making. Getting the details right is how they make good decisions and don’t have to stop and ask.

Correct information empowers your team to launch full speed ahead.

If a production team member is in the front office waving a work order and is asking, “Hey, what’s this mean?” It means you need help with getting the order information correct in the system so they can do their jobs.

Those are ten or fifteen minutes that you will never get back. How many shirts per hour in production did you just waste with that single question? How many more questions will be asked today?

It adds up.

Some key tips for you to use with your Information Audit:

- Start with order information intake. What questions are you asking? What needs to be mandatory? What type of training do your sales or customer service team need to do this correctly?

- Talk to your team. Where do they get stalled the most? Do this in every department. Interviews should be one on one and not in a group setting. Repeat answers provide the priority for change.

- Write it all down. It’s going to be a long list. That’s ok.

- Talk to key customers too. “We’re improving and need some feedback.” Don’t just send a survey. Their opinions matter. Have actual conversations.

- Keep thinking about how you can reduce friction and bottlenecks. Remember, you are only as fast as the slowest part of your process.

- Agree on common language and terms. What does “tonal” mean? What size does a “full front” indicate? Where is the standard placement for every different scenario your shop produces?

- How will you earmark and denote special instructions or placements?

- Look at past failures and errors. What information was needed that could have avoided those mistakes? Can you insert that into the process somehow?

Step Two: Preparation, Organization, and Delegation of Duties

I want you to stop thinking about this industry, and switch your brain to another one. Commercial restaurants. Specifically, the kitchen.

A well-run commercial kitchen in a restaurant is a model of efficiency and speed. Why? Because everything is about preparation, organization, and delegation of duties.

There is even a term for this that you may have heard before, “Mise en place.”

It’s a French term that literally means, “everything in its place”. This is an exact science, and they don’t fool around. Ingredients, spices, utensils, pots and pans, and other tools are all prepped, staged, and perfect before any work starts.

Chefs know that this is the key to running an effective kitchen with speed.

Now, I want you to think about your company. Every department. Are you constantly at the ready to work each day? Do you have a mise en place mindset?

Maybe. Maybe not. But I’ll bet you can do better.

Preparation

Shops typically think that this idea only applies to the production floor. But it matters just as much in sales, in the screen room, in receiving, and really in any department. When you don’t have to search for something, you are faster.

Your preparation determines the outcome. How prepared for work is every staff member each day?

Do they know what is expected of them? Is there clarity on what has to happen today? By lunch? What are the top priorities?

Is there any orchestration with other departments on what is needed for them to be successful today? How is that communication?

Do your team members have a routine that drives success for the day?

Rather than doing that in the morning when they come in, can you have them build that out at the end of the day yesterday, so when people arrive in the morning they are already prepared for the day?

Why waste time on the on-ramp, when you can be up to speed and on cruise-control immediately? That is what being prepared is all about.

Again, your preparation determines your outcome.

Try this experiment on for size. Go watch your production team first thing in the morning. Measure the time from when they clock in to the first completed shirt for every different piece of equipment. Don’t tell them what you are doing. In most shops that I have implemented this experiment in, the time is usually around twenty to forty minutes. If you are prepared, it can drop to about five to seven.

That time adds up.

Organization

This means that you need more organization. Mise en place. Common tools or items are always within an arms reach.

In production, the schedule is determined yesterday and that scavenger hunt has already happened. Jobs are laid out next to equipment the day before in the priority order they are to be produced. The goal is to have orders produced and ready to ship one business day before the posted ship date on the order. Everything is already there. Staff should never have to leave their stations to find screens, ink, thread, samples, approvals, or anything.

Everything is delivered to them. They should never have to stop and ask.

This is true of all departments. Everything is cycled through with each team supporting one another. It is not finger-pointing and bickering with a defend-the-castle attitude. You want high-functioning teams that are organized and supportive of the overall goal, which is customer happiness.

Delegation of Duties

In a commercial kitchen, different team members have specialized duties. That is true in our industry as well.

Smaller shops will have staff members handle many different tasks, but larger shops will have each employee focus on one aspect of the process.

Where shops lose speed, is with the thinking that nobody might occasionally need help. Or with the idea that you can delegate a task or function to someone so a higher priority action can get handled.

Your number one goal in production is to keep the machines moving. Downtime is cancer. You want to cut out as much as you possibly can.

A great production manager orchestrates this chaos by delegating tasks proactively. Check to make sure the screens for two days from now are burned are ready to go. What color inks or cones of thread will we need? Are we matching samples? Where are they? Is the inventory available for all of the orders?

They don’t have to do this work themselves. They simply need to make sure it gets handled. You want to be able to start staging tomorrow’s production sometime around noon today. This means everything has to be ready. But, if there is a straggler with an item, there is time to handle it.

In a commercial kitchen, the chef doesn’t do all of the cooking or ingredient prep. In your shop, that same mindset should be present with your production manager too. Delegation is the magic trick that makes that happen.

Step Three: Proper Technique

On this planet, in everything that needs to happen, there is a right way and a wrong way to do something. As humans, we instinctively know this.

But with anything that requires skill and craftsmanship, we might not actually know or understand something. So we “make it work.”

We start slapping bandaids on processes and techniques because “that order has to ship.” There never seems to be enough time to do things the right way.

But that is a lie you say to yourself.

Doing things incorrectly actually costs you time. You simply either don’t see it or passively choose to ignore it.

For example, let’s look at screen-printing an underbase white for a job on an automatic press. Raise your hand if your go-to procedure is to double-stroke that white ink screen.

Go ahead. Lift your arms up high!

Bandaid.

Circle back to the real reason why you have to double-stroke the underbase white (and maybe other screens too), it’s a lack of proper screen tension. You don’t measure this. Never have.

“It takes too much time”, you say.

But instead, you are spending an average of three to five seconds a print FOREVER, double-stroking that white underbase. How much time do you think that is a year?

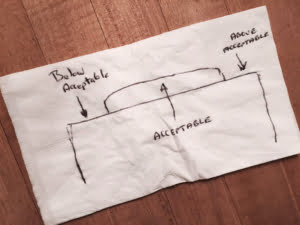

Let’s do some back of the napkin math. Let’s call it four seconds for the extra stroke. And that automatic press prints an average of 2,000 impressions per shift, per day.

4 seconds x 2,000 = 8,000 seconds

8,000 x 5 days a week x 4 weeks a month x 12 months a year = 1,9020,000 seconds.

Divide that by 60 for minutes = 32,000 minutes.

Divide that by 60 for hours = 533.33 hours.

Therefore, by double-stroking that underbase screen your shop is 533 hours slower than a shop that invests the time in doing things correctly. Give or take a few hours.

But Wait, There’s More

Without proper tension, multi-color jobs are harder to register. This means you are adding minutes to every set up unnecessarily.

Ideally, your shop should be setting up any screen-printing job in under five minutes or less. Manual or automatic, it doesn’t matter.

We already had one math problem in this article, so I won’t bore you with another. But think about what your shop’s average set up time is and why it can’t be under five minutes per screen.

How much extra time is this costing you a day in production due to a lack of proper screen craftsmanship? (Want to learn more? Read this)

Other Departments

That was only one example. In other departments in your business, they have to have proper techniques in their activities as well.

- Proper techniques in lead generation and closing sales

- Proper techniques in building and writing work orders

- Proper techniques in designing and building art files that work for production.

- Proper techniques in researching and ordering supplies, consumables, equipment, and other items

- Proper techniques in shipping and receiving for accuracy

- Proper techniques in other decoration methods such as embroidery, digital printing, dye sublimation, heat press.

- Proper techniques in post-production such as folding, hang-tagging, stickering, bagging, and boxing.

Everything you do in your shop needs to be process mapped out and reviewed. Is there a better way of handling something?

If you start with “Why?”, sometimes you can unlock a gem. As in, “Why are we doing it this way?”

Usually you’ll hear back, “It’s the way we’ve always done it.”

Is that a compelling reason to keep doing it the same way? I’ll bet you a cookie there could be a better way out there somewhere. As we proved earlier, saving four seconds can add up.

Step Four: Start With A Template

I like the idea of using a template as a starting point. A template is simply a set of pre-thought out ideas, whether mental or physical, to get something started.

Check out this photo:

Before our Shirt Lab Washington DC event, we were able to take some attendees down onto the field to watch batting practice for the Cubs vs the Nationals. I snapped this photo of the grounds crew laying out the home plate set-up. This is a simple wooden frame they are using to construct the markings at home plate. It’s a template.

Are you using templates in your shop? Think about how you can start.

Here are some examples:

- Checklist for discussion items or questions for sales or customer service.

- Pricing matrices are templates. Have pricing organized and ready to quote by deciding in advance how things should be quoted. Some shops have multiple scenarios based on who the customer is or their purchasing level. Everyone in the shop quotes the same because they are using the same mathematical formulas.

- Arrange some skids on the floor in shipping neatly in a row. As boxes are delivered from UPS, FedEx, or other shippers orders are segregated by the number of boxes. Skid one has single box orders. Skid two has orders with two boxes. This makes checking them in faster as the inventory is now grouped together.

- Pull all the orders for tomorrow and stage them next to the equipment in priority order. Use taped lines on the floor to mark where the boxes or carts should go, and line them up neatly with the floor marks.

- In the art department, have preset art templates created for different decoration locations. Guidelines and registration marks are already built and set on layers. Sizing an image is faster as you can just drop it in and scale quickly to the pre-set guideline.

- Common thread colors or ink colors are kept by the equipment so that nobody ever has to go find them. These are restocked as needed.

- Every desk, equipment station, or work area has a set of commonly used items for that department. They are organized the same way. Workers can shift from station to station and instantly find something because it is in the same type of location at the workstation.

- Organize everything in the shop for orders by the last digit of the work order number. If your job number is 123456, the inventory is pre-staged in the “6” row so production can find it easily when they pull the order for production. Documents and work orders are kept in the “6” bin in the office until needed. After production, if the order is to go the customer pick up route, it is staged on the “6” shelf in shipping for easy location and retrieval.

Did This Article Cover Everything?

Of course not. There are thousands of ways to introduce speed in your shop. I didn’t touch on employee training. Equipment. Or even automation.

What you should be doing is constantly thinking. Don’t settle for the status quo.

Right now your main competition is trying to get to same or next day shipping. It’s happening.

Where do you think that is going to leave you if you are stuck in the seven to ten business day turnaround like a lot of shops?

Speed kills. Don’t let it kill you.

“If someone is going down the wrong road, he doesn’t need motivation to speed him up. What he needs is education to turn him around.” – Jim Rohn

“I’ve always found that the speed of the boss is the speed of the team.” – Lee Iacocca

“Bad news travels at the speed of light. Good news travels like molasses.” – Tracy Morgan

Are you currently struggling in your shop trying to recover from the effects of the pandemic?

My new book, “Moving Past Disaster: Develop Your Business Next Normal” is built to help you rethink and retool your business for what is happening now.

In the book, you will snapshot your current situation, use proven creative mental modeling exercises to develop new ideas to combat the current crisis, develop those into a new business plan, and built out a two-year action plan for success.

I know this can help you. Get going with change that can make a difference today.