Recently in a few decorated apparel social media groups that I’m in there has been some debate about the merits of digitally printing t-shirts. Some say that you can’t make any money doing it. Others point out that there are problems with the printed results and the printheads constantly fail. All in all, digital printing is a big loser and not worth our time.

Really?

The grumbling sound of disharmony among the decorated apparel community on this topic is perfect fodder for a blog article!

The first thing that we should get out of the way is a common misconception about digital printing. Screen-printers will always compare it to their brand of production. Will it ever be the same?

No way. Digital printing is something completely different.

Screen-printing is a Lion. Digital Printing is a Cheetah.

Lots of similarities, but mostly completely different animals. If you are a screen-printer and you want to really understand digital printing, you have to stop thinking about it like it’s the same animal you’ve been working with all these years. Just relax.

It is different because of how it works. First and foremost, you are using water-based four color process ink to print the image. This means that the final printed image is completely dependent on the quality of the file, and the skill of the person doing the prep work. Shit in, shit out as they say.

Because it’s four color process, you will never hit a Pantone color with an exact match. You can come close, and there can be a lot of effort to calibrate the final print with some Photoshop based color correction actions…but you’ll never hit PMS 186 exactly. Some of the newer hexachrome systems produce better results. You’ll get a nice red, but not that exact one. For exact, you’ll need to print that spot color. In some circles, that’s a non-starter. For others, a nice red will be fine.

What’s the trade-off then? Well, mainly that you can print millions of colors on a shirt without any halftones. Why worry about just hitting one specific color when you can print with photographic quality?

For the people in the “hit the PMS color” camp, I think we’re talking about the wrong thing. Instead of focusing on that one color limitation, why not illustrate the benefit of a larger printed color palette on the garment? I’ll take millions of colors any day. Just call me greedy.

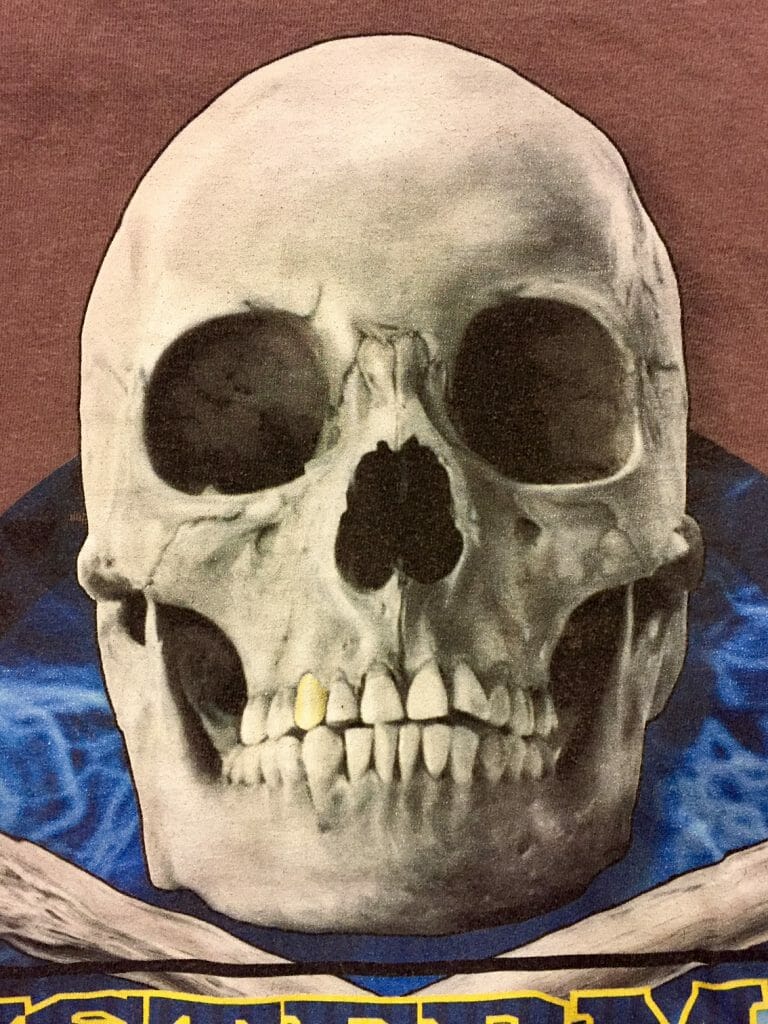

Check out the photo for this article for example. This is a detail for a shirt I designed for a guy’s trip last year for my group of knucklehead friends. I took this photo this morning on my kitchen counter of the t-shirt. It’s been washed probably twenty or thirty times since then. Vivid color, tight detail, zero hand on the shirt. This was printed on a brick colored Authentic Pigment Garment dyed t-shirt, which I really like. I couldn’t do that with screen-printing without a flock of screens on the press, which for two dozen shirts wouldn’t be worth the effort.

Reconsider How You Educate Your Customer

That’s great, but Marshall, I just print for the corporate world. How can I sell to them? They always want their logo in exact Pantone matches! They have to have their logo printed in a spot color!

Do they?

I’ve seen corporate logos printed CMYK in plenty of magazines. All were four color process, not spot. Probably didn’t hit those Pantone colors either…but were close. Why is that any different? Tons of companies are even getting their business cards printed digitally these days too. I’ve seen them. Those digital color matches aren’t perfect either. Close again. So is the only time that corporate client has to have an exact color match is on a t-shirt? Please…

When you are talking color with your customers are you educating them about the expectations of CMYK digital printing? Showing the differences and being transparent with the process? Teach your customer how the cheetah hunts. They already know how the lion feeds.

Print Biology 101

So if screen-printing is a stately lion, why is digital printing a cheetah?

That’s easy. Speed. That’s why it’s the cheetah. And by speed, I don’t mean how fast it prints “on” the shirt. The speed we are talking about is avoiding all the “normal” work involved in traditional screen-printing. Let’s elaborate and show how the cheetah hunts.

Digital printing has tremendous workflow advantages. While you’ll never want to print a 10,000 piece order with digital equipment, running those “under 100” piece orders might make more sense. How many of those do you do a day?

What makes digital printing faster is that you aren’t monkeying around with the screen prep, press registration, ink mixing or other set-up steps that traditional analog screen-printing employs. Don’t forget about reclaiming and emulsion coating either. Have you ever timed all of those steps and added up the minutes? Try it. You’ll be surprised at the amount of time and labor you spend getting ready to print.

For digital, the art still has to be prepped, but even that can be automated. Lots of companies right now have their art sent directly from their webpage to the print queue in their digital printer. This lowers the traditional transactional cost of a work order as it’s already set up. Shirts are pulled and staged, and the job is printed. No order entry. Packing lists are printed at the end of the dryer belt. The order is boxed up and is ready to go in about the same amount of time it would take to burn and dry the screens if you printed it the traditional way. Cheetah workflow speed kills. Especially if you are competing in the online world. This is why Amazon just purchased a small army of Kornit presses and placed them in Texas.

Hold Onto Your Butts. (My favorite line from Jurassic Park)

Digital printing isn’t going to quietly fade away somewhere. In fact, you are going to hear more about it in the future as the technology increases you’ll see printing speeds and color matching capabilities increase. Hexachrome print heads for example add two more colors (orange and green) to CMYK, so there’s an expanded color gamut and that means spot color matching is more feasible. If you have an online ordering presence, this is how your competition is going to be handling their production, especially in the 48 piece or less variety.

Why carry preprinted inventory for an online store, when you can simply stock the blanks and print them as they are being ordered? If you print for retail, don’t think that this system isn’t being discussed on some board room table right now.

The new Kornit Vulcan reportedly prints around 250 shirts an hour. Other digital equipment manufacturers will catch up too. One day a shirt will just simply be printed much like a color copy; all in a single pass of the print head. Zip. Done. Will you be part of the conversation then?

What Are the Limitations?

The pretreatment step is crucial. This is where a lot of first time users, or people considering a digital system fail. Until the inks can simply be printed onto the shirt by themselves, this is the stuff that has to be applied for dark garments to set up the white and colors to lay down on top of the fabric. For white shirts it isn’t necessary.

Kornit owns the patent for the inline process, which is simply the best way to do it. Hands down.

For all other manufacturers, it’s an outside step or something you have to do with a separate machine. This means you are touching the shirt more, which impacts your workflow and labor costs to produce the order. Also, the pretreatment fluid has to be controlled exactly. Too little or too much can have adverse affects on the print. Dialing this in is mandatory to achieving the results you crave.

Not all shirts work well with a digital printer either. Garment dyed and even some brightly colored regular t-shirts, such as Sapphire, have issues too. For those the pretreatment can turn the shirt a little yellow sometimes. Also, results can vary from dye lot to dye lot depending on the shirt manufacturer. Misting with a water in a spray bottle helps, but it is unreliable. The shirts I used in the example above, yellowed with the pretreatment, but spraying water around the image before the dryer step took it out. It’s just one of those things.

Polyester tends to repel the water based ink, but some colors (white or lights) and brands can work ok. It’s a trial and error thing. Supposedly, everyone is working on inks that work on polyester.

What shirts work best? Normal 100% cotton. All day long.

Number One Digital Printer Issue: Clogged Print Heads

This is the biggest headache for a lot of shops. Although the color print heads can clog, the challenge lies mainly in the white print head due to the nature of the titanium dioxide that comprises white inks. It just loves to clog up like bran muffin and cheese day at the retirement home.

If you read the comments by DTG owners (or former frustrated owners) this is the challenge that drives them nuts. The expectation for any device is that you should be able to use it when you want. And that’s perfectly fair. No argument.

For digital though, if the user just let’s the machine sit idle there’s a good chance that the print heads will clog up. This is why a lot of systems have print heads that purge or weep ink constantly to prevent the clogging. That leads to increased costs as all that purging ink is going down the drain. Newer systems have been addressing this issue by engineering methodologies to deal with the clogging and purging challenge.

Think Before You Buy

Lastly, I’d like to point out a common problem with shops that purchase a digital printer and that is that they didn’t invest the time to construct a solid business plan to sell digital printing. You would think they would as these things aren’t cheap by a long shot. For a lot of shops, it is a shiny new toy that they play with for a bit, and then it sits in the corner waiting for the “right job” to come along so they can use it. If you never sell digital printing to your customers, will that “right job” ever come along organically?

I can’t tell you how many shop owners I’ve talked or corresponded with about their unhappiness with their digital printer. They complain how it sits idle, and then when they have a job for it the equipment fails them. My premise is that they failed the printing equipment by not thinking about how they should be selling digital printing before even considering buying one. Was there even a demand in their market? Are they working to create one? Usually not.

So it sits gathering dust until they decide they want to dump it for $4,000 on an internet site. You’ve seen them.

Recommendation? Find a Partner

My recommendation for people who are interested in a digital printer for their shop is to find a trusted contract printer that has the equipment and can do a good job for them. They then can sell the services and learn how to talk to customers about it, how to create or preflight the art files for optimum print quality, and what the overall expectations with the system will be. Once you are selling enough to flood your contractor with work, and it gets painfully obvious you should be doing it yourself…then drop the hammer on spending that cash for the equipment.

I know as professional decorators we all want to do things ourselves, as that’s the craftsman in us coming out. We’re tinkerers. However, learning to sell digital printing is like anything else…there’s a learning curve, vocabulary, price resistance, customer misunderstanding of the platform, art considerations, and other things you have to overcome. Why not just give up some of that margin to a printer and learn all that before getting into potentially buying a very expensive paperweight if you aren’t successful with your sales strategy?

Test the Waters

There are plenty of decorators out there that you can test their capabilities.

One idea is to design a test shirt. Have plenty of gradient blends, textures, subtle areas, PMS colors to match, and tricky problems to solve. Choose a few shirt colors and send a sample order to three or four potential contract printing partners. Give everyone the same deadline and instructions. Get everything back and see who wins.

The money you just invested in the samples will determine who has the best cheetah.

That’s your new best friend.

8 comments

Jorge Salcines

Hello from Texas. You do a great job in thoroughly explaining the difference between the two. and how they are both relevant. Keep sharing your great posts.

atkinsontshirt

Thanks Jorge!

Betty Gichuki

Jambo (hallo) from Kenya! My husband and I recently started a garment decoration company called Create A Tee (createatee.co.ke). We are using Kornit Technology and so far so good. We read your articles alot and we just soak in their content. The recent one of lions and cheatehs just hit home. We are possibly the first company to use DTG in Kenya so we have quite a few challenges but immense possibilities. Anyway, just thanking you a lot.

atkinsontshirt

Awesome!! This is exactly why I write this blog!! Keep on learning!!!

J

Who knows whats going to happen with the DTG market and how it affects the apparel industry exactly. I presume that it will continue to get better and faster, and probably in a couple of more years really be the dominating print method for brand’s retail online sales. We did our due diligence a couple years ago. We looked at all the DTG’s on the market and found the Epson 2000 to be the best and most capable single shirt printer on the market outside of the Kornit brand. We spent 19k for our printer and 3 months later Epson marked the printer down to 14995. That killed the equity the machine had immediately. It was a slap in the face. Not only that, but before the first year is out the Epson f2000 seems to clog no matter what you do to make sure it doesn’t. You can perfect humidty, cleaning processes, and knowledge to keep the printers from clogging and they still will. Until that is fixed, DTG will never be King. Thanks for the articles as always Mr. Atkinson.

atkinsontshirt

Thanks for reading and commenting… I appreciate your viewpoint but only time will tell.

Peter Walsh

Marshall: Thanks for your interesting and timely blog on the impact of Digital Direct to Garment Printing technology on the decorated apparel market. I amazed to read some of the posts on Social Media and in Industry Forums from screen-printers who blast DTG technology and claim that it has a limited future due to slow production speeds, higher ink cots, reduced versatility and lower perceived quality than what can be achieved by screen-printing. An important factor that these printers overlook is the ability of DTG to “PROFITABLY” print as few as one shirt of a custom design. The Online Garment decorators have discovered that people will pay $25 or more for a custom tee shirt.

These companies don’t care that it costs $2 or $3 more to print the image with DTG than it would with screen-print, when they can sell the finished garment for two to three times what they could sell a mass produced screen-printed tee for. Another thing that these Online Companies do really well is to make it easy for their customers to purchase from them, by offering up highly functional websites supported by effective “self-service” online design studios. These companies don’t treat people as P.I.T.A customers for not meeting minimum quantities, and generally speaking they deliver the goods within the agreed upon schedule.

My fear is that every time a traditional garment decorating company turns away a customer who wants to purchase 6, 12, or 18 shirts because their order doesn’t meet shop minimums, they are helping to build a competitive channel that could be just as devastating to their business, as Walmart has been to small town retailers.

atkinsontshirt

Exactly. The future of our industry is changing every single day. What will it look like ten years from now? Will traditional screen-printers be akin to paper letterpress shops? Probably not, but digital has a huge foothold and will only grab more marketshare. Adapt or die.